INSULRECYCLE®

Insulcap® is now greener on the inside.

Up until now the thermal barrier market was focused on managing the mechanics of heat, looking more at reflection, conduction and convection risks to goods.

With increasing costs of resources and energy, every effort has been made to establish thermal barriers that are efficient to make and easy to handle.

With an increased use of thermal barrier material for one-way transport globally, the cost of disposal at end-of-life and the environmental impact of increasing landfill is now becoming of greater importance. These factors have been the catalyst for the development of materials and systems to answer these issues.

Wilpak Group International next generation thermal barriers effectively manage the mechanics of heat, while being efficient to manufacture and handle.

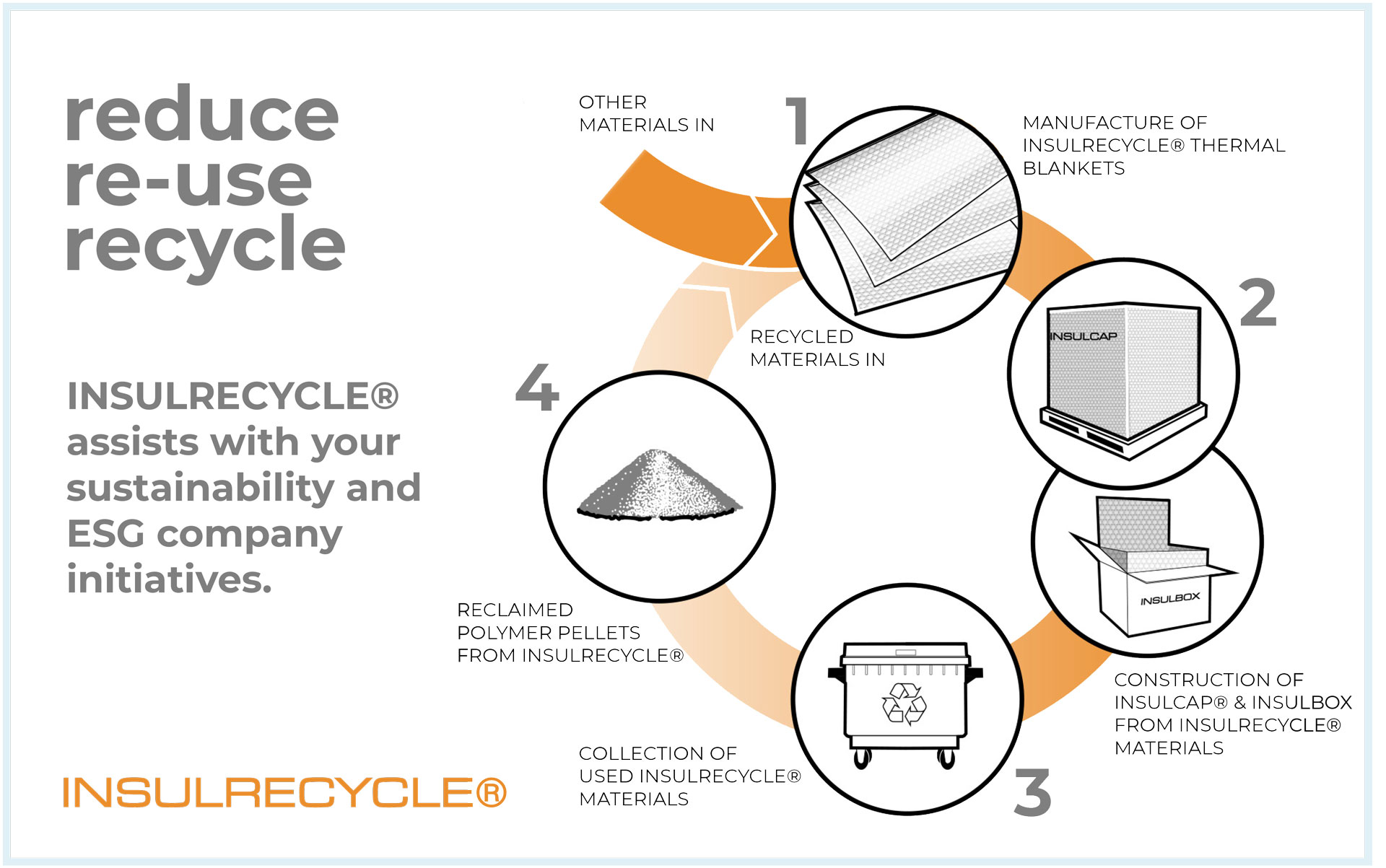

INSULRECYCLE® thermal barrier materials are made from recycled content and are recyclable ‘end-of-life’, reducing environmental impact by avoiding landfill as waste.

INSULRECYCLE® from Wilpak Group International is the thermal barrier innovation of the future.

A HIGH PERFORMING AND RECYCLABLE SOLUTION THAT IS AVAILABLE NOW!

INSULRECYCLE® VALUE

PRODUCT FEATURES | CUSTOMER BENEFITS |

|---|---|

Constructed from recycled content | Reduced demand for new materials |

Fully recycleable materials | Reduced waste and environmental impact |

Lightweight thermal protection barrier | Easy and safe to handle |

Tough thermal barrier materials | Reliable and Reusable |