Case study

Pre Qualification - Insulcap

Our lnsulPlatinum® & lnsulGold® thermal covers are passive systems designed specifically for the purpose of shipping temperature-sensitive products via air freight.

Top Line Results

Use of both the lnsulPlatinum® and lnsulGold® thermal cover systems achieved a duration of 120:00hrs between 2.0°C and +30.0°C, when tested in extreme conditions that meet both Summer and Winter ambient temperature profiles of a Top 5 Pharmaceutical Company.

insulplatinum® & insulgold®

Purpose

The purpose of this document is to detail the thermal performance of both the WilPak lnsulPlatinum® & lnsulGold® thermal cover systems per the mission requirements and procedure outlined below.

Both types of thermal covers were tested with both a minimum and maximum payload configuration.

These tests were conducted in an ISO 170025 Accredited laboratory, with established requirements to simulate how well it could protect the goods of a Top 5 Pharmaceutical company, as we transported those products around the world, going through both Summer and Winter temperature profiles.

Products Tested

- InsulCap® thermal blanket (pallet cover), with InsulBase thermal pallet liner.

- InsulPlatinum® maximum performance thermal barrier material (double foil).

- InsulGold® high performance thermal barrier material (single foil)

Payload Configuration

- Minimum Payload: 100kg of 5mL Pre-Filled Saline Syringes

- Maximum Payload: 200kg of 5mL Pre-Filled Saline Syringes

Test Start Date – End Date

- 21 October 2022 – 13 November 2022

The thermal covers were tested with both a minimum and maximum

payload configuration.

The thermal performance results are summarised in the Table “Thermal Performance Results” and represent the first product probe, from each shipper, to record an excursion outside of the 0.0°C to +30.0°C temperature range.

insulplatinum® & insulgold®

Results

The thermal performance results are summarised in the Table “Thermal Performance Results” and represent the first product probe, from each shipper, to record an excursion outside of the 0.0°C to +30.0°C temperature range.

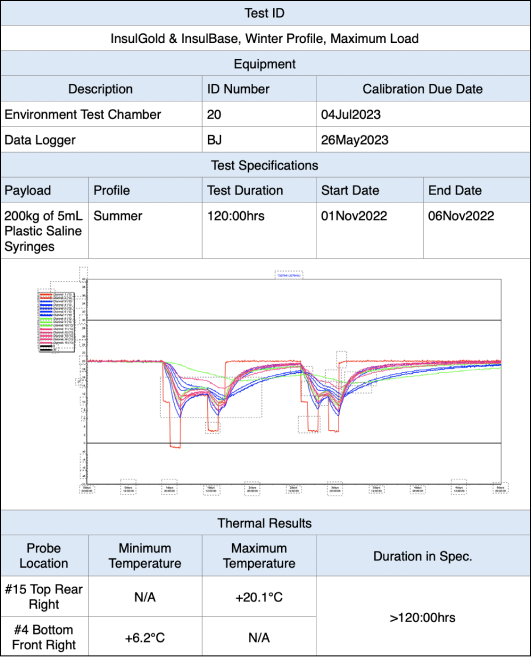

Table: Thermal Performance Results

| System | Ambient Temperature Profile | Payload | Required Pass Duration | Duration between +2.0°C and +8.0°C |

|---|---|---|---|---|

| InsulPlatinum and InsulBase | Summer | Minimum | 120:00 hours | >120:00 hours |

| Winter | Maximum | 120:00 hours | >120:00 hours | |

| InsulGold and InsulBase | Summer | Minimum | 120:00 hours | >120:00 hours |

| Winter | Maximum | 120:00 hours | >120:00 hours |

insulplatinum® & insulgold®

Detailed Analysis

Scope

- The scope of the qualification work is limited to the thermal testing of both the WilPak lnsulPlatinum® & lnsulGold® thermal cover systems against Summer and Winter ambient temperature profiles.

- Testing was performed using both a minimum and maximum load configuration as outlined in Section 6.4.

Material & Equipment

Laboratory (Controlled Enviroment)

This section outlines the key materials and equipment that were required to accurately test the thermal performance of the WilPak lnsulPlatinum® & lnsulGold® thermal cover systems.

Equipment List

- lnsulPlatinum® Thermal Covers (1260.0×1260.0x1300.0mm)

- lnsulGold® Thermal Covers (1240.0×1240.0x1300.0mm)

- lnsulBase Thermal Bases (1400.0×1400.0mm)

- Environmental Chamber (20)

- 5mL Saline Syringes

- Eltek Thermocouple Temperature Data Loggers

- Type ‘T’ Thermocouple Wires (24 Gauge)

Equipment Calibration

The data loggers have a resolution of 0.1 °C and a measuring accuracy better than ±0.5° C within the test temperature range. The data logger was programmed to record temperatures at 10-minute intervals for the duration of the thermal testing process. The accuracy of these environmental test chambers conforms to ±3.0°C at any point within the useable space of the chamber, with an average rate of change of ±0.5° C per minute across the range.

These allowable tolerances may be referenced for each temperature set point listed in this report. Copies of the calibration documentation showing equipment-specific tolerances are provided in Appendix B.

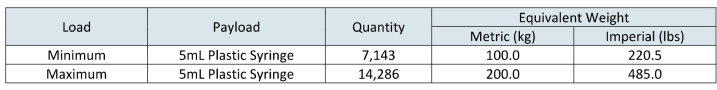

Payload

The WilPak lnsulPlatinum® & lnsulGold® thermal cover systems were tested with both a minimum and maximum payload. The minimum payload represented the least thermally stable configuration and was in the form of 100kg of pre-filled 5mL saline syringes. The maximum payload was in the form of 200kg of 5mL pre-filled saline syringes.

The table below indicates the quantity of the product and its equivalent weight used for thermal testing.

Table: Payload Description for Thermal Testing.

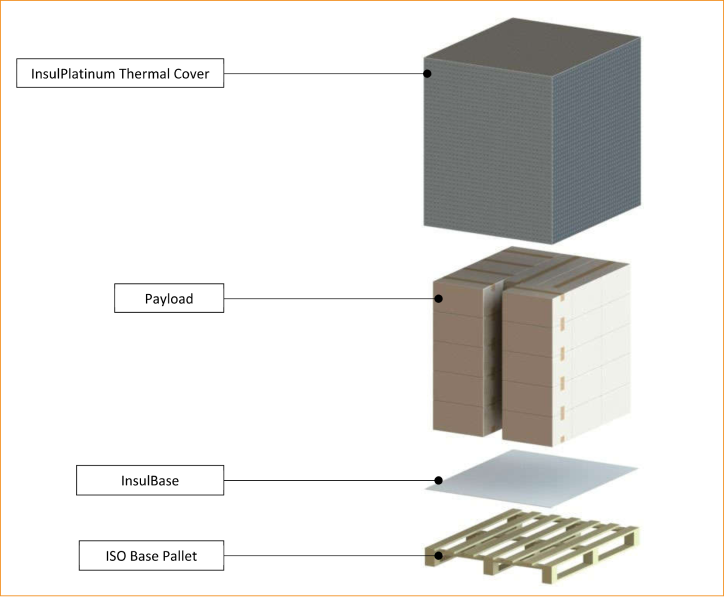

InsulPlatinum & Insulbase

System Diagram

Test Procedure

Product & Probe Information

Product Preparation

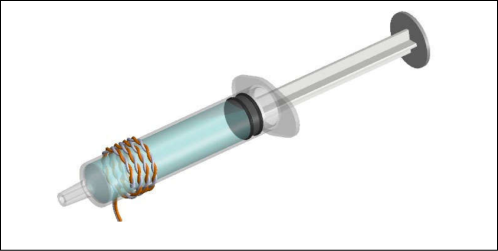

Payload products for both the minimum and maximum loads were prepared with calibrated type T thermocouple probes. The ends of the probes were wrapped around the circumference of the syringe three times to ensure contact with the product and taped securely in place to minimise the risk of movement from the probe during the testing process. The prepared product was positioned within the payload cartons.

Figure: 3.5mL Plastic Syringe and Thermocouple Probe

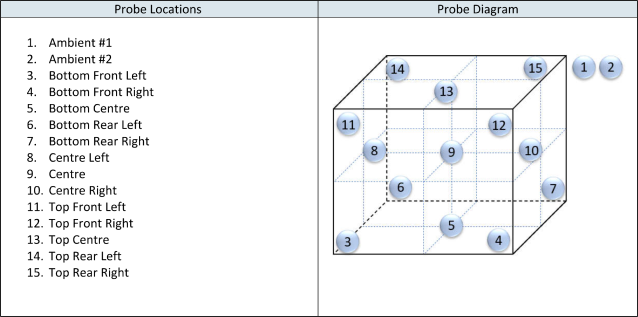

Probe Locations

To accurately record the internal temperature of the systems when tested, each internal probe was attached to the product and placed in the stated locations shown in Table 9. The probes were connected to the corresponding channels on the data loggers, and the loggers were placed outside of the chamber while the product was being conditioned or tests were being run. At least one probe from each logger recorded the internal ambient temperature of the chamber. This setup was repeated for all tests.

Table: 3.5mL Probe Numbers and Location used in Thermal Testing.

insulplatinum® & insulgold®

Conclusion

Deviations and Discussion

The temperature profiles were designed to meet the needs of a Top 5 Pharmaceutical Company and to be representative of normally encountered conditions. The profiles are general simulations and are not intended to represent a worst-case exposure.

Conclusion

Use of both the lnsulPlatinum® and lnsulGold® thermal cover systems achieve a duration of >120:00hrs between 0.0°C and +30.0°C when tested to both Summer and Winter profiles that meet the needs of a Top 5 Pharmaceutical Company.

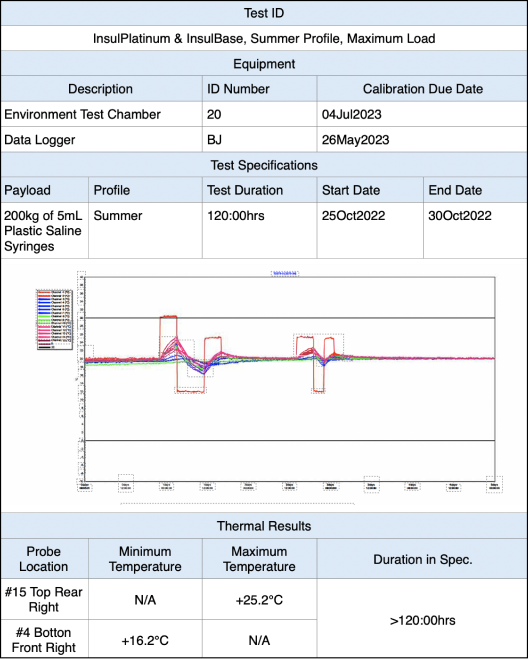

Table: Results for InsulPlatinum Thermal Testing Summer Profile.

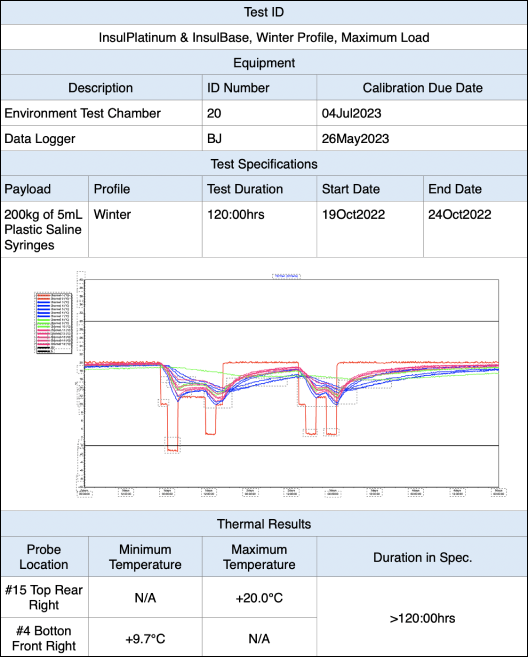

Table: Results for InsulPlatinum Thermal Testing Winter Profile.

Table: Results for InsulGold Thermal Testing Summer Profile.

Table: Results for InsulGold Thermal Testing Winter Profile.